|

| Aaron Stebner |

|

| Douglas Van Bossuyt |

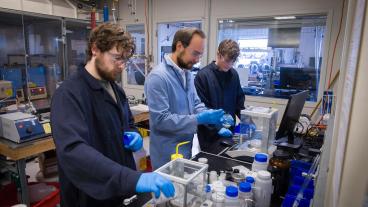

GOLDEN, Colo., Dec. 14, 2015 – Mechanical Engineering Assistant Professors Aaron Stebner and Douglas Van Bossuyt were awarded a $2.5 million Advanced Industries Accelerator grant from the Colorado Office of Economic Development and International Trade (OEDIT) to establish a 3D metal printing research consortium. Mines is building out 2200 sq. ft. of dedicated laboratory space in the new Coorstek Center for Applied Science and Engineering for the consortium, while industry members Lockheed Martin, Ball Aerospace, Fauston Tool and Manufacturer’s Edge, are providing more than $4.5M of initial investment in the program. The combination of funds will help position Colorado as the leader in the advancement of standardization, qualification, and intelligent digitization of 3D metal printing.

“By hosting the center at Mines, students will be the primary researchers and our state will be a national leader at training the 3D printing workforce,” Van Bossuyt said.

The center will be dedicated to performing applied research and creating database infrastructure needed to qualify 3D printers and their parts in a timely, cost-effective manner. Large businesses will be able to rely on the center to help accelerate their technology development cycles, while small manufacturing businesses will be able to supply certified 3D printed metal parts to advanced industries.

“Central to our consortium is the creation of a high fidelity, intelligent database for purposes of qualifying, calibrating, and optimizing 3D metal printers and parts for any business wishing to enter the market,” Stebner said.

Some of the highlights of the program are two U.S. firsts: 1) Mines will perform research together with Faustson and Concept Laser on the first U.S. installed dual-laser 3D metals printer—a technology that will reduce manufacturing times. 2) Mines will also acquire the first U.S. university-owned X-ray Diffraction Microscope capable of both Diffraction Contrast Tomography and submicron-resolution Computed Tomography for purposes of advanced microstructure characterization of 3D printed metal parts.

Over a 12-month period, Mines researchers will demonstrate the capabilities of the center’s infrastructure through two pilot research projects on 3D printed nickel and titanium alloys. The research performed in the consortium will benefit five advanced industries: Advanced Manufacturing, Aerospace, Bioscience, Energy and Natural Resources (including Clean Technology), and Infrastructure Engineering. The center will also offer workforce-training programs at Mines and other Colorado educational institutions, as students have access to the world-leading facility and research.

“Graduate students and post-doctoral scholars employed in our center will become leading research and development scientists and scholars for this industry,” Van Bossuyt said.

With support from this funding, together with the undergraduate curriculum pioneered by Van Bossuyt, Mines anticipates graduating more than 100 students proficient in additive manufacturing each year.

View the full release from OEDIT.

Contact:

Kathleen Morton, Digital Media & Communications Manager / 303-273-3088 / kmorton@mines.edu

Karen Gilbert, Director of Public Relations / 303-273-3541 / kgilbert@mines.edu