Additive manufacturing of shape memory alloys creates efficient, eco-friendly cooling technology

The Alliance for the Development of Additive Processing Technologies (ADAPT) at Colorado School of Mines was part of an international research team that developed a new elastocaloric cooling material that is highly efficient, eco-friendly and easily scaled-up for commercial use.

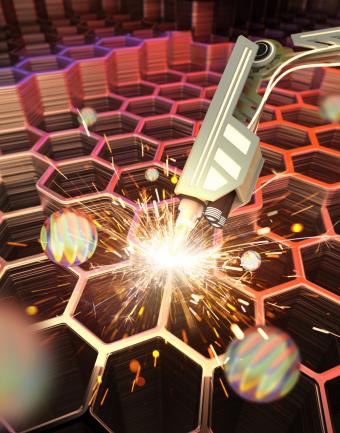

The new cooling material is a nickel-titanium alloy that was sculpted using additive manufacturing techniques.

The work, which was published in the Nov. 29 issue of Science, is the result of a collaboration led by researchers from the University of Maryland, together with Ames Laboratory, Mines, Iowa State University and China’s Xi’an Jiaotong University.

“The key finding of the research is that while elastocaloric materials typically used for solid-state cooling show a degradation in cooling behavior after hundreds of cycles, laser melting these metals creates fatigue-resistant nanocomposite microstructures that can cycle, with consistent cooling capacity, a million times,” said Aaron Stebner, Rowlinson Associate Professor of Mechanical Engineering and a co-author of the paper.

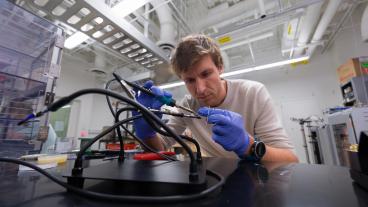

Mines PhD candidate Nathan Johnson, postdoctoral scholar Cheikh Cissé and Mechanical Engineering Associate Professor Mohsen Asle Zaeem were also among the paper’s credited authors.

ADAPT’s role in the research was directly related to the other work the consortium has done on shape memory alloys, specifically nickel-titanium. Johnson conducted the in situ diffraction work, and Cissé performed the finite element modeling. X-ray diffraction was used on the additively manufactured samples to verify that phase transformation was happening, was reversible and was not changing its behavior through many cycles. It was also used to verify different phases in the material that made up the nanocomposite microstructure.

Cooling technology, used in refrigeration and HVAC systems around the globe, is a multibillion-dollar business. Vapor compression cooling, which has dominated the market for more than 150 years, has not only plateaued where efficiency is concerned but also uses chemical refrigerants with high global warming potential.

Solid-state elastocaloric cooling – where stress is applied to materials to release and absorb heat – has been under development for the last decade and is a front-runner in alternative cooling technologies. Shape memory alloys are found to display a significant elastocaloric cooling effect; however, the presence of hysteresis — work lost in each cycle and the cause of materials fatigue and eventual failure — remains a challenge.

To that end, the international team of collaborators led by University of Maryland Professor Ichiro Takeuchi developed the improved elastocaloric cooling material using a blend of nickel and titanium metals, forged using a 3D printer, that is not only potentially more efficient than current technology, but is completely “green.” Moreover, it can be quickly scaled for use in larger devices.

“Dr. Stebner’s expertise played a crucial role in developing understanding of the fundamental mechanism behind fatigue-resistant behavior of additive manufactured shape memory alloys. His group’s in situ synchrotron diffraction and finite element modeling capabilities gave us unique insight into the inner workings of the material,” Takeuchi said.