Mine waste offers new path to sourcing critical minerals, sustainable construction materials

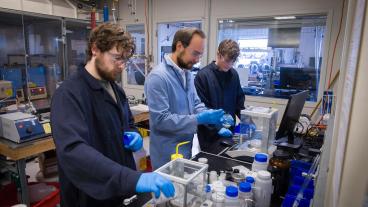

Reza Hedayat, associate professor of civil and environmental engineering at Mines, is developing scalable processes to turn mine tailings into high-value construction materials—and the process is closely tied to critical minerals extraction.

Mining companies face a tough balancing act: meeting the surging demand for critical minerals—such as lithium, cobalt and rare earth elements vital to energy, communication, medical and defense technologies—while managing the environmental and financial costs of mine waste.

Mine tailings—the material left over from everyday mining operations—are often seen as waste and a growing environmental concern. But Reza Hedayat, associate professor of civil and environmental engineering at Mines, sees them as an opportunity to both scale up the extraction of essential minerals and develop more sustainable construction materials.

Hedayat’s research team is developing scalable processes to turn mine tailings into high-value construction materials, such as geopolymer bricks, lightweight aggregates and ceramic tiles. These materials are designed to meet strict performance standards while reducing the mining industry’s environmental footprint. And while the primary focus is on reuse, the extraction of critical minerals is closely tied to the process.

It's a practical solution to a demanding challenge.

Making waste work harder

Rethinking what happens to mine waste by transforming it into something useful could unlock significant opportunities for both critical mineral supply and sustainable materials.

“Imagine you have an ore body, and within that ore body, you have certain traces of critical minerals that are economically viable to extract. Eventually, in many cases, over 90 percent of the original ore body will end up in the form of finely ground residue that is not economically viable for processing, and that type of waste is deposited in a landfill or deposition areas,” Hedayat explained. “This non-critical component, though economically deficient, may still have valuable components in that they can be converted via fairly inexpensive methods to become sustainable, durable construction materials.”

This dual-use vision—recover what you can, reuse what you can’t—could be vital for strengthening domestic critical mineral supplies while advancing sustainable construction. Creating marketable materials from tailings also opens new revenue streams, helping mining companies offset costs and ride out market volatility.

“Our goal is to create a sustainable, economical and scalable pathway for reusing mine waste, while supporting the critical minerals and material supply chain and promoting a circular economy,” Hedayat said.

Supporting a circular economy

That circular mindset reframes tailings not as a burden to manage but as raw input for the next generation of building materials. The approach reduces demand for raw materials, cuts carbon emissions and extends the lifecycle of extracted resources.

“Our work directly advances a circular economy model in mining by transforming mine tailings into valuable, durable and sustainable construction materials, thereby closing key resource loops and extending the lifecycle of extracted materials,” Hedayat said.

And the benefits are multifaceted. Instead of stockpiling or disposing of tailings, Hedayat’s technologies, when adopted at large scale, can convert them into valuable materials. And by replacing natural resources like clay, shale and stone with mine tailings, the technologies can decrease the need for additional mining and quarrying, reducing resource depletion, carbon emissions and land disturbance.

Hedayat also envisions the deployment of bench-scale—and eventually pilot-scale—facilities near mine sites that would promote the localized reuse of waste, reducing transportation impacts and generating regional economic activity.

“Our work aims to shift mine tailings from end-of-life waste to new beginnings as feedstock, exemplifying how mining byproducts can fuel sustainable construction and contribute to a low-waste, low-emission future,” Hedayat explained.

It’s a vision that resonates with policymakers and industry alike. Hedayat’s research was already selected as part of the U.S. Department of Energy’s efforts to increase the efficiency of domestic critical minerals production through the co-manufacture of value-added products. But turning that vision into reality will take more than lab success.

Hedayat points to the need for broad collaboration—with mining companies, universities and government agencies—to ensure site-specific adaptability and scalable solutions. Policy support will also be essential, from funding pilot projects to streamlining approvals for integrated recovery and reuse operations.

In other words, sustainable materials and critical mineral supply chains don’t have to be separate goals. With the right technology and partnerships, they can support each other—and help reshape the mining and construction industries into a more resource-efficient cornerstone of the U.S. and global economies.

Watch this video to dive deeper into the construction materials Hedayat’s team is working on.

Explore more of how Mines is leading innovation in critical minerals at mines.edu/critical-minerals-research.