Critical Minerals Week: Mines researchers leading collaborations to increase domestic mining, secure supply chains

Mines PhD student Karlie Hadden MS ’24 weighs out a sample of sparamine concentrate to run through a RO-tap machine.

By Sarah Kuta, Special to Mines Research

Critical minerals are in “just about everything we use,” according to Elizabeth Holley, a Mines associate professor of mining engineering. From our laptops and cell phones to the transmission lines that deliver electricity to our homes, these naturally occurring compounds have become a major part of our daily lives—likely without us even realizing it.

However, many critical minerals are difficult to obtain—or could become so in the future—because they are extracted and processed in other countries, including some that have strained relationships with the United States. Against the backdrop of the world’s ever-shifting geopolitical landscape, the nation’s industry and government leaders are exploring the possibility of producing more of these minerals domestically.

Making this shift will be challenging, but Mines researchers are confident it can be done. Experts in everything from metallurgy to anthropology are teaming up to chart a path forward for critical minerals in the U.S.—work that will likely have major implications for national security, the economy and the environment.

Interdisciplinary, cross-campus collaboration

The U.S., like many other countries, maintains a list of critical minerals—those considered essential to the nation's economy or security and at high risk of supply chain disruption. The current lineup is expansive, covering “more than half of the periodic table,” said Holley, one of the Mines researchers leading the charge to help America produce more of its own critical minerals. Well-known household names like nickel and copper are on the list, alongside lesser-known elements like praseodymium and hafnium.

Mines researchers have been studying critical minerals for years. But those efforts ramped up and coalesced roughly five years ago, when the university, in partnership with Fort Lewis College, was awarded a grant from the National Science Foundation’s Growing Convergence Research program. Since then, this interdisciplinary team, led by Holley and Nicole Smith, a cultural anthropologist in the Mining Engineering Department, has received nearly $9 million in funding for a portfolio of related projects. Those projects include support from the NSF, the Department of Energy, the DOE’s Critical Materials Innovation Hub led by Mines Research Professor Rod Eggert, the Alfred P. Sloan Foundation and the Resilient Energy Economies Initiative, as well as industry partners.

Key to the group’s success has been a focus on deep and meaningful collaboration, bringing together scholars from a wide variety of backgrounds to tackle this pressing problem.

“It’s a very powerful cross-campus effort that is not just on paper,” said Holley, the principal investigator on the National Science Foundation grant. “We’re all working in concert, and that’s a huge achievement.”

Three pathways for domestic production

The Mines team is working on a suite of different projects to understand the issue from every possible angle.

“All of our projects examine the technical, as well as the social, environmental and policy considerations, of increased domestic production of critical minerals,” said Holley. “What does responsible mineral production look like? What are some of the challenges? Where are the opportunities? Where are the bottlenecks and supply chain risks?”

They are also looking into the economics of critical mineral production, to understand whether the practice is financially viable in the U.S.—and, if not, what types of incentives might be introduced to make it so.

Their research focuses on different minerals and sites, but they all fall under three possible pathways for ramping up U.S. production: new mines, byproduct recovery and mine waste.

Some case studies relate to the development of new mines, or operations created specifically to extract critical minerals. In Idaho, for example, Mines researchers are investigating the possibility of mining cobalt by looking at the mineralogy of the deposits, where and how these elements could be recovered and how the proposed activities intersect with global supply chains and the priorities of communities and local economic development organizations.

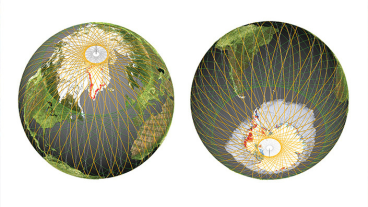

Researchers are also considering byproduct recovery, or trying to get more critical minerals out of existing, active mines. New research led by Holley finds that the U.S. could drastically reduce or even eliminate most of its critical mineral imports if mining companies extracted more critical minerals from already mined ore.

For example, gold mines in Nevada contain abundant arsenic and antimony—however, at the moment, most of those critical minerals get thrown away because it’s not profitable for mining companies to extract them. Similarly, more cobalt could be recovered from U.S. copper mines, and more nickel could be gleaned from platinum and palladium mines, according to Holley.

“The geological endowment is there, it’s just that it’s not economically viable to recover these minerals—so, the next question is, what do we need to do to change that?” said Holley. “Our team is working on policy, as well as technical research and development, to lower the costs and recover more critical minerals.”

The third angle they’re exploring is mine waste. This involves recovering critical minerals from tailings, or the leftover materials after a mining company has extracted its target product. For example, some Mines researchers are trying to figure out how to recover copper from a wastewater treatment plant near Idaho Springs, while others are investigating the possibility of recovering zinc and other critical minerals from tailings at active and abandoned mines across the country.

At first glance, the byproduct recovery and mine waste pathways may seem similar. But Holley uses a household waste analogy to explain the difference: Byproduct recovery is like trying to use more of an ingredient in your kitchen before tossing it in the trash, whereas mine waste is like recovering useful materials from the landfill.

Community support and social acceptance

Regardless of which pathways the nation chooses to pursue, community acceptance and participation will be vital. That’s why the Mines team includes experts like Smith.

Through qualitative and quantitative research, Smith and her colleagues are trying to understand social dimensions of the entire critical mineral supply chain—from mining to processing to refining. In southeastern Missouri, for instance, her team is investigating community perceptions of a forthcoming cobalt mine.

“Some of the questions our group is asking include what factors influence the social acceptance—or rejection—of critical minerals development in the U.S.?” she said. “What does acceptance actually look like on the ground? In the push to secure domestic supply chains, what kinds of tradeoffs or liabilities are emerging, either here or abroad?”

Mining companies understand that community engagement is critical for the success of their projects. Does that engagement take on new urgency—or a different form—when it comes to critical minerals? That’s another question Smith and her colleagues hope to eventually answer with their research.

“We’re also trying to understand if the critical minerals narrative is gaining traction among local communities and the broader public and whether this, in turn, contributes to increased social acceptance of these projects,” she said.

In an ideal world, communities would become “equal partners” in critical mineral projects, to help ensure they’re developed in a just and responsible way, according to Smith. In addition, mining companies would hold themselves to strict environmental standards—even if federal regulations loosen.

If not, Smith said, “they run the risk of repeating environmental and social injustices, particularly against Indigenous and other marginalized communities.”

Guiding national strategy

Mines researchers have made great progress on understanding the barriers and opportunities for domestic critical mineral production, according to Holley. Looking ahead to the near term, their focus will shift toward transforming those findings into actionable recommendations.

“By identifying those sites, minerals and scenarios, we’ll be able to give policymakers a list that basically says, ‘OK, choose your own adventure. You’re worried about gallium? These are your best options,’” said Holley. “Our work is poised to guide national strategy.”

Explore more of how Mines is leading innovation in critical minerals at mines.edu/critical-minerals-research.