Mines researchers leading the fight against 'forever' chemicals

Persistent chemical compounds are lurking in our water supply, making their way into drinking water, agriculture and other consumables. How do we begin to treat this problem and make our water safe again?

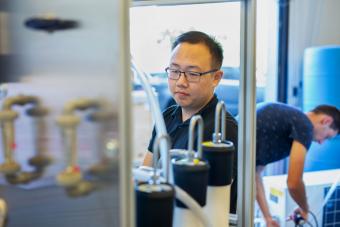

Charlie Liu, a PhD candidate in civil and environmental engineering, works on a pilot water treatment system to test how well a combination of filtration and destructive ultraviolet light would clear perfluoroalkyl substances, or PFASs, from groundwater.

Photo by Joe DelNero, Colorado School of Mines

By Jenn Fields, Special to Mines Newsroom

Summer is a quiet time on college campuses, but in July, Mines PhD candidate Charlie Liu was hard at work prepping a pilot water treatment system for a U.S. Air Force field test.

Liu spent one of the hottest days of the year in the cool of the General Research Lab, weaving in and out of various systems Mines researchers had designed and built to treat water contaminated with a persistent chemical compound that poses a serious threat to human health.

Christopher Higgins, professor of civil and environmental engineering and one of Liu’s advisors, began leading the charge on what has become a multidisciplinary hub of research in this field at Mines years ago. His latest research is unveiling an uncomfortable truth: that this family of chemicals, called PFASs, might be more widespread than anyone knew.

The system Liu was working on with faculty members would test how well a combination of filtration and destructive ultraviolet light would clear perfluoroalkyl substances, or PFASs, from groundwater. As a category of chemicals, PFASs are a growing problem around the globe. They’re found in products from firefighting foam to nonstick cookware to pizza boxes and popcorn bags, and they’re easily transported in water. The research on their effect on human health is ongoing, but there’s evidence PFASs can cause cancer and developmental, endocrine, renal and metabolic problems.

PFASs from firefighting foams have contaminated entire aquifers and watersheds, shutting down municipal water supplies and agricultural operations and exposing thousands of people, pets and even the food supply to these chemicals. More than 400 military sites have PFAS contamination, which in some cases has spread to wells and municipal water supplies in nearby communities, leading U.S. Secretary of Defense Mark Esper to announce immediately after taking office in July 2019 that his first act would be to create a task force to address PFASs.

While Mines researchers have fostered partnerships with epidemiologists and toxicologists for expertise on the biomedical side of the PFAS problem, Higgins has turned his attention more toward fate and transport. “How they move from soil to groundwater, how quickly they move in groundwater, those sorts of things,” he said.

One of the other challenges for water-treatment specialists is figuring out how to remove and destroy them. PFASs are so persistent that people working on the problem have started calling them “forever chemicals.”

"They do not break down on their own, so we need engineered solutions for these particular contaminants,” said Timothy Strathmann, a professor of civil and environmental engineering who is part of a team at Mines working on PFASs. “There are a lot of contaminants of concern, but many of them will biologically break down over time. What’s exciting for me as a technology developer is we really do need new technologies for these chemicals.”

Mines is a leader in research in PFAS remediation, fate and transport, and exposure. Higgins is the lead researcher on a nearly $2 million grant from the Environmental Protection Agency that will look at whether it’s enough to remove “forever” chemicals from drinking water now that they’ve also been found in food from farms in areas with contaminated water. The exposure question, he said, is a big one. “How are we being exposed to these chemicals, and what are the most important ways people are being exposed?"

The exposure question is complicated, but it tackles the most basic questions people in communities with contaminated water are asking. “When we go out to these communities, the first thing people do is they get bottled water, and they’ll even get treated water, but the question is, is it still OK to shower in the water?” Higgins said. “If you irrigate your backyard garden with contaminated water, or if your local community garden has contaminated soil, is it safe to eat that food?”

He was quick to note that the Mines-led team wouldn’t be doing the risk assessment—results from a parallel toxicology study are needed to address that question. Instead, the team would track the important question of just how the chemicals move through the environment and how people are exposed to PFAS contamination in the first place.

Though PFASs have been around for a few decades, recent exposure cases have put the problem on the radar of government agencies, private companies and the public. Right now, there are federal health advisory levels for just two PFASs — perfluorooctane sulfonate and perfluorooctanoic acid — in drinking water. “It’s all happening at once,” said Chris Bellona, an assistant professor of civil and environmental engineering whose expertise in water treatment and reuse includes PFAS remediation. “The regulatory environment is trying to figure itself out, because there’s not a lot of toxicological data for a lot of the compounds. We didn’t really know the best way to treat these compounds, so we’re trying to figure that out. And the public’s trying to figure it all out — the level of contamination and occurrence nationwide is fairly unknown.”

Higgins said he’s constantly recruiting more experts for PFAS projects, and Mines now has a small army of scientists working on the problem. “It’s dozens of people, if you count the grad students and faculty, not to mention the undergraduates,” Higgins said. At Mines, which has experts in water across disciplines, he’s found a trove of colleagues who can attack the PFAS problem from different angles.

He’s also working with a surprising number of Mines alumni in this field. “When you look out at who is doing this research around the country, it ends up being a lot of Mines graduates,” Higgins said. “We’re recruiting new experts, but it’s also Mines alumni out there who are making a difference, and it’s at the state and federal agencies and also academics.”

Two of those future alumnae are working on fate and transport research with Higgins now. PhD student Anastasia Nickerson is working on a characterization project at three Department of Defense sites that are being sampled at high resolution for both groundwater and soil. “With the instruments in our lab, we have a chance to look for a much broader spectrum of compounds and not even necessarily know what we’re looking for going in,” she said. “The goal is to get a more comprehensive understanding of what’s happening at these sites, because there can be a transformation of these compounds once they’re on the site. Ultimately what we’re finding is that there’s a lot of variety and high concentrations of compounds that most people aren’t looking for.”

Juliane Brown’s research interest is in the human health risk assessment associated with consuming PFAS-contaminated produce and, specifically, PFAS uptake into the edible parts of plants. “This is a question we’re getting from farmers and backyard gardeners,” said Brown, another PhD candidate. Like Nickerson, she’s looking at a variety of compounds, including precursors that can transform into recalcitrant PFASs. “Most of the people who have done plant-uptake experiments have only looked at a few individual PFASs,” she said. “What we haven’t looked at as much is mixtures, precursors and newly discovered contaminants. We need to start to get a handle on these other compounds that could be in the soil or irrigation water to see if they could potentially get into the edible portion of the plant.”

Treatments for PFAS-contaminated water

There are two ways to get PFASs out of water: remove them or destroy them. Removal treatment processes use some form of filtration, such as activated carbon absorption to separate PFASs from water, but the PFASs are then trapped in the media that filtered them, and that must be disposed of safely. So Mines researchers are looking at the best ways to separate the chemicals from water, as well as technologies that will destroy them — and the best way to combine separation and destruction.

"You have your separation processes, like a membrane or absorbent materials. These are separation processes —they’re very efficient for getting the chemical in the water down below these really low health advisory levels,” Strathmann said. “But you create this byproduct stream. So ideally you would then have a second type of technology, a destructive approach.”

Strathmann is experimenting with a hydrothermal process to destroy PFASs. “What this uses is elevated temperature and pressures in water,” he said. “If you heat water under elevated pressure, water takes on new properties to make it more reactive. What we’ve found is this enhanced reactivity of the water is able to destroy these very recalcitrant chemicals, because they can bring about the destruction of these carbon-fluorine bonds that are normally very resistant to breaking because they’re among the strongest chemical bonds in nature.”

The pilot system for the Air Force that Liu was working on over the summer uses ultraviolet light as the destructive process on a concentrated waste stream after filtration. “We’re evaluating this concept of mixing media,” Bellona said, explaining that combining technologies was part of one of his U.S. Department of Defense grants. “Should it have activated carbon prior to ion exchange? Or what if you had mixed media—so, activated carbon and ion exchange in one vessel? What if you had ion exchange before granular activated carbon — is there any benefit there?” Another of Bellona’s DOD grants looks at life cycle cost and impact for PFAS treatment technologies.

PFASs made headlines in recent years after high-profile contamination cases came to light, including when the city of Fountain, Colorado, learned their drinking water supply had been contaminated with PFAS from firefighting foam used at a nearby Air Force base. Because Mines has a track record in PFAS contamination research, the city came to them to work with their water utility to clean the town’s drinking water supply.

Faculty and students built a pilot system for Fountain that let them test four different media side by side. “It operated for seven months and we never had a single problem with it,” Bellona said.“It’s completely automated. It’s still running right now.”

The system Liu was preparing for deployment at an Air Force base was related to the work in Fountain, and working on the project at Mines had many benefits. “We can build everything here, we test on real groundwater and we can analyze everything,” Liu said. “I always challenge myself to know everything in the process, so I built all of these systems, and then I run all the samples and process them all and understand the results, so I understand the whole process. And Mines lets me do that."

Mines doesn’t just open doors for building pilot systems. Higgins acquired two high-resolution mass spectrometers for the water lab’s work in detecting and quantifying various types of PFASs, as well as searching for unknowns, to create a PFAS library of sorts. The school also has a wastewater treatment plant on campus, which lets researchers work with “real water at real flow rates,” Bellona said. “The work that we’re doing, I don’t know if it would be possible at any other university,” Bellona said. “We have such unique capabilities. All this equipment, it’s automated, fully field-deployable, we built it ourselves. We also have all the analytical equipment to test for these compounds, so the thing that really differentiates us from any other research labs is that we do things on scales that allows people to make decisions about full-scale treatment."

(This story first appeared in the 2019-20 issue of Mines Research Magazine. Read it and more in the interactive digital edition of the magazine.)