Capstone Design team qualifies for finals in NASA human lander competition

Student-led design targets dust, rock that gets kicked up when rockets land on surface of Moon

Colorado School of Mines has qualified for the finals of NASA’s 2024 Human Lander Challenge (HuLC) Competition.

The Capstone Design student team, comprised of seven mechanical engineers and three electrical engineers, will compete against 11 other collegiate teams this June in Huntsville, Alabama, where they will present their final concept to a panel of NASA and industry experts.

Teams were challenged to design solutions for lunar plume-surface interactions (PSI) for NASA’s Artemis campaign, which will establish a long-term human presence on and around the Moon.

PSI is the dust and rock that gets kicked up and swirled around when a rocket lands on the surface of the Moon. The swirling dust and rock can damage habitats and scientific experiments, as well as endanger rockets landing on the Moon, which can draw up the large rocks and debris into their exhaust and other components.

“Everything Mines has taught us has led up to this,” said Ethan Adam, a senior in mechanical engineering and the team leader. “And it’s really paid off.”

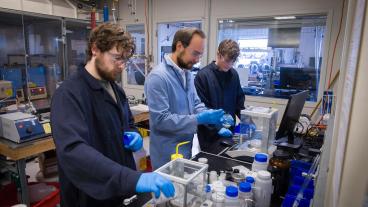

The Mines team – Prudent Landers-FAST, short for “Fresnel Assisted Sintering Technology,” started meeting in August for roughly four hours a week to research and meet with clients. Testing the theory and building the prototype began this semester.

Their solution involves a large-scale Fresnel lens, which acts as a magnifying glass, focusing sunlight underneath it and creating heat. The heat will turn the regolith, or the blanket of loose sediment on the Moon’s surface, into a solid brick that the rockets can then use as a landing pad, thus avoiding the potentially damaging stir of dust and rock.

Adam said previous research suggests the use of a Fresnel lens to melt down regolith, but the idea hasn’t been tested or considered for landing pads for a rocket.

During the team’s testing of the prototype, the lens was able to reach a temperature of 647 degrees Celsius (1200 Fahrenheit) in less than 4 ½ minutes. The goal temperature for the moon is 1200 Celsius.

But even at the lower temperature, the regolith simulant was heated up enough to form a solid rock after a short time under the Fresnel lens.

To qualify for the NASA finals, the team underwent a rigorous assessment of their proposal. Each finalist team received a $7,000 stipend award to facilitate further development of their proposed concept and their full participation in the 2024 HuLC Forum in Huntsville. The top three winning teams will share a prize of $18,000.

The Mines team presented their project at the Capstone Design Showcase on April 25. Now, for the HuLC Forum in Alabama, the team is working on a maintenance and construction plan for the design to be implemented on the moon’s surface. The team will also be creating an automated prototype of the final design.

Other team members include, Noah Pruitt, Alex Fisher, Madeleine Nightengale-Luhan, Aiden Semet, Max Pizzimenti, Harrison Fugate, Justus Quint von Lengerke, Cora Perkins, and Casey Hubbs.

Adam will continue to work in the aerospace industry after the forum, too. His role as team leader for the HuLC Competition helped him land a full-time position as a systems engineer at Northrop Grumman starting in the fall.