Zac Snyder, a senior in mechanical engineering, and Ryan Lam, a senior in electrical engineering, make adjustments to their 3-D printed RC car parts in the Labriola Innovation Hub. Their Capstone Design team won funding from the InnoHub E&I Prototyping Fund to help cover the cost of developing the parts. (Photos by Tim Meyer/Colorado School of Mines)

In Introduction to Automotive Design, car crashes are part of the learning experience.

Students in the Mechanical Engineering elective are given a radio-control off-road truck and a singular goal: Make whatever modifications their team deems necessary to make the RC car go as fast as possible in a straight line by the end of the semester.

“You basically turn it into a drag car," said Juani Dassie, a senior in mechanical engineering who took the class last year. “Students get really creative – they do a lot of stuff to it, and they crash them a lot, which brings the issue.”

Frequent crashes plus high speeds can equal broken parts, which in turn can result in costly delays, both financially – a replacement roll cage, for example, can easily run a team $150-$200 – and in lost learning time waiting for replacement parts to arrive from the manufacturer.

With help from the Labriola Innovation Hub’s E&I Prototyping Fund, Dassie and his Capstone Design team have come up with a solution: Redesign the most frequently damaged parts so they are stronger, easier to dissemble and 3-D printable right here on campus.

“If something’s broken, they won’t have to spend the $50 or whatever it costs to order the part,” said Hunter Miller, a senior in mechanical engineering. “They can just go to the makerspace or the print rooms and print the part for $1 or if it’s under a certain amount, it would be free for the students completely.”

Figuring out exactly how to best 3D print those parts in the first place, though, is much more expensive. The team homed in on 11 individual parts, from the roll cage and bumper to the strut tower and control arms, to improve, with only a $500 budget from their Capstone project sponsor.

“It doesn't actually come cheap when you're doing a lot of 3D printing and testing, because we have to print these parts so many times and test different infills and different strengths and everything, as well as order pieces like ball bearings that we need to insert into our parts to test them,” Miller said.

So, they applied to the ProtoFund and were awarded $500 in their first semester and up to $500 this semester to build their prototype truck parts. Student-led teams can receive up to $500 from the ProtoFund in the first round of funding and up to $2,000 in the second round.

“It's been super beneficial for us to actually be able to try different ideas and move forward with a design that maybe wasn't the perfect design right from the start and being able to redo things and go back and actually improve our designs, instead of planning for one thing and sticking to that,” Miller said.

The workshops and mentorship that ProtoFund teams have access to have also been helpful to their project, Dassie said.

“They have given us a lot of feedback on how to set up prints, so they print correctly. What materials to use? What are some good practices? Bad practices?” Dassie said. “Stuff like that sometimes goes over our head, because for me at least it's my first time really doing a lot of printing. There's a lot of mistakes that we avoided.”

The team will present their final project at the Fall 2025 Capstone Design Showcase on Dec. 4 and the Fall 2025 InnoHub ProtoFund Showcase on Dec. 8.

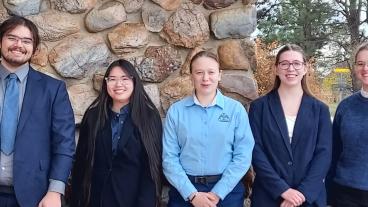

In addition to Dassie and Miller, team members include mechanical engineering senior Zac Snyder and electrical engineering seniors Ryan Lam and Owen Duffert. Lam and Duffert are focused on creating an external real-time battery monitoring system for the truck, another request from their project sponsor.

Intro to Automotive Design classes could start 3-D printing the team’s parts as soon as next semester – and be back to focusing on building the fastest RC cars possible.

“When I took the class, we had issues with the strut tower – it broke one time we crashed the car and because it took so long to get the part, we resorted to just gluing it together and it didn't work really well,” Dassie said. “Every other time we finished the run and we were hitting the brakes, the car broke again. It was very annoying, and it could have been solved if we just printed a new part and you are back to full strength.”

To learn more about the ProtoFund and apply for the next round of funding, visit the Labriola Innovation Hub website.