An assistant professor of chemical and biological engineering at Colorado School of Mines is working to develop a material to fill cavities while stimulating teeth to rebuild themselves—an innovation that would change the face of dentistry.

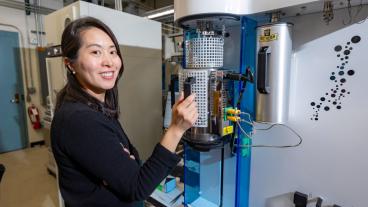

Melissa Krebs, whose research is focused on tissue regeneration, recently received one of Delta Dental of Colorado Foundation’s 2016 Innovation Grants, which will fund the development of mineralized materials with various formulations and the testing of how dental pulp stem cells react to these materials.

“We started a little over two years ago, working on mineralized materials to mimic bone, for bone regeneration,” Krebs said. A postdoctoral research associate on her research team, Jacqueline Harding, an inorganic chemist by training, “started exploring the mineral phase more than we had initially intended to,” Krebs said, and this resulted in a material that could be “tuned” to mimic the minerals in enamel, the visible part of the tooth, and dentin, the layer underneath the enamel.

The current treatment for cavities calls for dentists to root out the decay and fill the cavity with materials such as amalgam (an alloy of mercury, silver, copper and other metals), composite resins, porcelain and gold. “It’s purely a restoration of function,” said Krebs, who notes that this treatment is often painful, costly, cosmetically undesirable and “ultimately results in further deconstruction of the tooth matrix, which must be repaired.”

The material Krebs, Harding and PhD candidate Matt Osmond are developing would be applied to a cavity as an injectable hydrogel or moldable putty, depending on the size of the repair. While serving as a filling, it would biodegrade over time while recruiting tooth cells to make collagen, the building block of nails, hair and teeth, and mineralize it to restore the original structure of the tooth. “The material provides them something they can move into, and gives the right mineral signals for regenerating,” Krebs said.

The ability to tune the mineral content of the material to the environment of the implant site is unique to Krebs’ team. “Others have not taken the time to fine-tune the chemistry,” Krebs said. “We have more control than I’ve seen in the literature, and the ability to do it all from the same starting product—I haven’t seen anyone else do that.”

Contact:

Mark Ramirez, Communications Manager, College of Applied Science & Engineering | 303-384-2622 | ramirez@mines.edu

Ashley Spurgeon, Editorial Assistant, Mines magazine | 303-273-3959 | aspurgeon@mines.edu