Colorado School of Mines researchers are part of a multi-institutional team that has discovered a way to create new alloys that could form the basis of next-generation semiconductors.

A paper on that work, titled “Novel phase diagram behavior and materials design in heterostructural semiconductor alloys,” was published in the journal Science Advances on June 7, 2017. Coauthors include Mines Associate Professor Brian Gorman, adjunct faculty Ann Deml and Research Assistant Professor Andriy Zakutayev in the Metallurgical and Materials Engineering Department, and Physics Research Professor David Ginley. Zakutayev and Ginley are both joint appointees with the National Renewable Energy Laboratory, which led the study.

Semiconductor alloys already exist—often made from a combination of materials with similar atomic arrangements—but until now researchers believed it was unrealistic to make alloys of certain constituents.

“Maybe in the past scientists looked at two materials and said I can’t mix those two. What we’re saying is think again,” said Aaron Holder, a former NREL postdoctoral researcher and now research faculty at the University of Colorado Boulder who is the corresponding author of the paper. “There is a way to do it.”

Scientists connected to the Center for Next Generation of Materials by Design (CNGMD) made the breakthrough and took the idea from theory to reality. An Energy Frontier Research Center, CNGMD is supported by the Energy Department’s Office of Science and researchers from NREL, Colorado School of Mines, Harvard University, Lawrence Berkeley National Laboratory, Massachusetts Institute of Technology, Oregon State University and SLAC National Accelerator Laboratory.

“It’s a really nice example of what happens when you bring different institutions with different capabilities together,” said Holder. In addition to Ginley and Zakutayev, his coauthors from NREL are Stephan Lany, Sebastian Siol, Paul Ndione, Haowei Peng, William Tumas and John Perkins.

A mismatch between atomic arrangements previously thwarted the creation of certain alloys. Researchers with CNGMD were able to create an alloy of manganese oxide (MnO) and zinc oxide (ZnO), even though their atomic structures are very different. The new alloy will absorb a significant fraction of natural sunlight, although separately neither MnO nor ZnO can. “It’s a very rewarding kind of research when you work as a team, predict a material computationally and make it happen in the lab,” Lany said.

Using heat, blending a small percent of MnO with ZnO already is possible, but reaching a 1:1 mix would require temperatures far greater than 1,000 degrees Celsius (1,832 degrees Fahrenheit), and the materials would separate again as they cool.

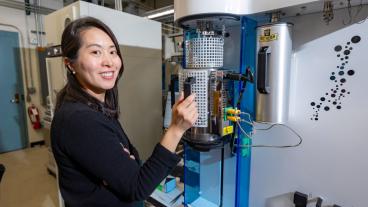

The scientists, who also created an alloy of tin sulfide and calcium sulfide, deposited these alloys as thin films using pulsed laser deposition and magnetron sputtering. Neither method required such high temperatures. “We show that commercial thin film deposition methods can be used to fabricate heterostructural alloys, opening a path to their use in real-world semiconductor applications,” Zakutayev said.

The research yielded a first look at the phase diagram for heterostructural alloys, revealing a predictive route for properties of other alloys along with a large area of metastability that keeps the elements combined. “The alloy persists across this entire space even though thermodynamically it should phase separate and decompose,” Holder said.

Funding for the research came from the U.S. Department of Energy’s Office of Science.

Contact:

Mark Ramirez, Managing Editor, Communications and Marketing | 303-273-3088 | ramirez@mines.edu

Ashley Spurgeon, Assistant Editor, Mines Magazine | 303-273-3959 | aspurgeon@mines.edu