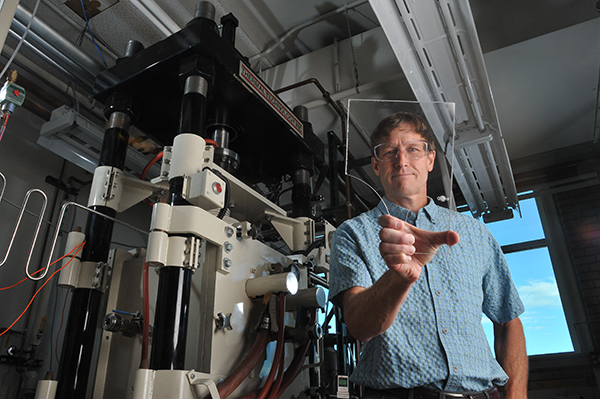

Colorado School of Mines has been awarded a multiyear contract by the Usable Glass Strength Coalition to conduct research that improves the understanding of the strength properties of manufactured glass products at the smallest scale. “The opportunity to apply the most modern, atomistic-level tools to examine strength-limiting flaws in glass is truly inspiring, and we at Mines are looking forward to making an impact,” said Metallurgical and Materials Engineering Professor Ivar Reimanis, who is leading the research project.

“The opportunity to apply the most modern, atomistic-level tools to examine strength-limiting flaws in glass is truly inspiring, and we at Mines are looking forward to making an impact,” said Metallurgical and Materials Engineering Professor Ivar Reimanis, who is leading the research project.

The research project, titled “Fundamental Understanding of Strength Limiting Flaws in Multi-Component Glass,” will be funded at $80,000 annually for at least two years and go beyond the standard fracture mechanics approach to predicting failure. In high-strength glasses in particular, flaws either start or are the result of processes at the atomic or nanometer scale.

Mines researchers will use a combination of fracture testing, nanoscale characterization and modeling to describe how cracks form, employing modern instrumentation such as focused ion beam sectioning, atom probe tomography and state-of-the-art electron microscopy to allow previously unachievable levels of resolution and analytical information.

The team will also study how these flaws form during processing or handling in specific situations, such as in the container and fiber industries.

MME Research Assistant Professor David Diercks and Materials Science PhD student Aaron Miller are performing the atom probe tomography work, while MME undergraduate student Joseph Van Sant will design and use an environment-controlled glass strength testing apparatus.

Mines’ proposal was chosen out of 13 submissions and is the second project the UGSC has funded. “Research such as this with Colorado School of Mines is essential,” said Robert Weisenburger Lipetz, USGC secretary and administrator and executive director of the Glass Manufacturing Industry Council. “Although a ubiquitous and extremely versatile material, it is well known that glass is subject to fundamental flaws, it fractures, and to make it strong enough to use, it is heavy.”

Weisenburger Lipiz said understanding why glass fractures could lead to new manufacturing processes and glass that is lighter and tens or hundreds of times stronger than what is currently in use. “It would revolutionize the use of glass as a material and have a huge impact on sustainability objectives,” he said.

Glass research is on the rise at Mines, noted Reimanis. In May, the MME department was awarded a three-year, $230,000 contract by Corning Incorporated to examine contact damage in display glass, research that will play a part in the development of next-generation Gorilla Glass for smartphones and other devices. Reimanis is also the principal investigator in this project, assisted by PhD candidate Brian Campbell Davis. Also, MME Assistant Professor Geoff Brennecka is leading the construction of a glass shop in Hill Hall, which will teach students how glass is made.

“Glass is a very interesting material that is still not well-understood,” Reimanis said. “There are many different tunable parameters one can use to influence properties.”

Contact:

Mark Ramirez, Communications Manager, College of Applied Science & Engineering | 303-384-2622 | ramirez@mines.edu

Ashley Spurgeon, Editorial Assistant, Mines magazine | 303-273-3959 | aspurgeon@mines.edu